- Home

- Products

- Marine Hose

- Floating Hose

- Tanker Rail Floating Hose

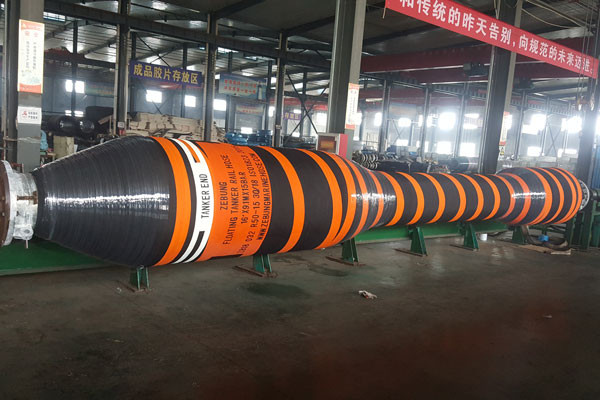

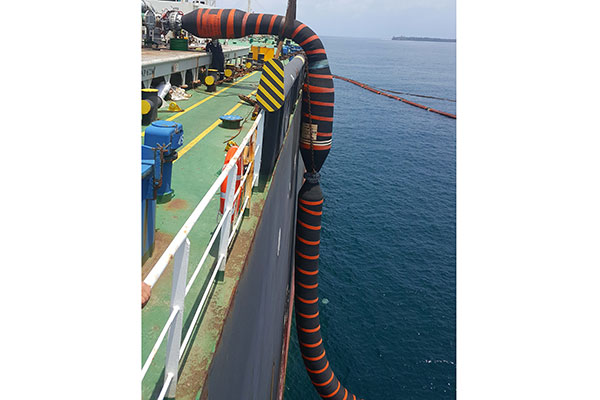

Tanker Rail Floating Hose

Installed on the ship's side, tanker rail floating hose is designed for connecting with pipeline end manifolds (PLEMs) of a floating production storage offloading (FPSO) unit.

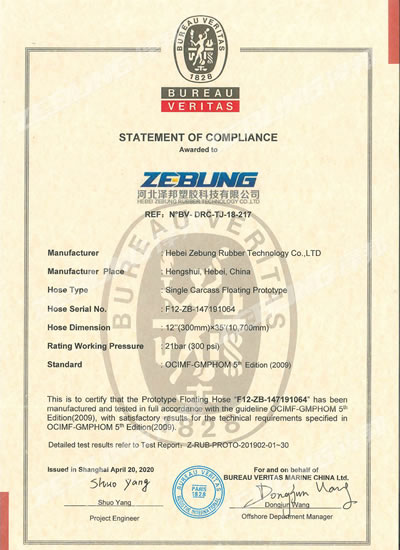

Tanker Rail Floating Hose Testing

During the production, the marine floating hose can be tested according to either the GMPHOM 2009 quality standards or the standards specified by the customer, ensuring high safety and performance of marine hoses for using in the marine environment.

Features

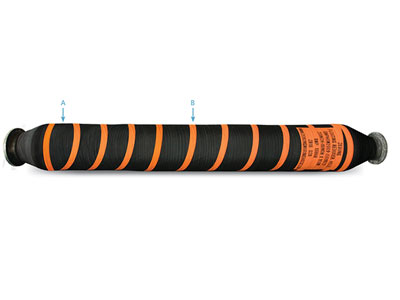

1. Floating hoses available with single and double carcass design

2. Rated working pressure: 21 bar

3. Minimum reserve buoyancy: 20% or as requested

4. Electrical continuity: electrically discontinuous

5. The tanker rail floating hose comes with a reliable and efficient leak detection and indication system. The detector will quickly respond to the leak after detecting the damage of main carcass. In this case, the operator can remove the damaged hose in a quick manner. This greatly reduces economic loss and impact on marine environment.

Technical Parameters

| Inner Diameter mm |

Weight in Air Empty kg |

Outside Diameter mm |

Min. Bending Radius m |

||||

| 9.1m | 10.7m | 12.2m | A | B | C | ||

| 150(6") | 524 | 576 | 628 | 500 | 290 | 440 | 0.6(2.0') |

| 200(8") | 726 | 817 | 908 | 560 | 350 | 530 | 0.8(2.7') |

| 250(10") | 931 | 1037 | 1143 | 690 | 420 | 530 | 1.0(3.3') |

| 300(12") | 1091 | 1225 | 1359 | 810 | 490 | 640 | 1.2(4.0') |

| 400(16") | 1650 | 1839 | 2028 | 1000 | 580 | 840 | 1.6(5.3') |

| 500(20") | 2200 | 2550 | 2800 | 1100 | 720 | 1000 | 2.0(6.7') |

Note: Specifications can be made upon request.

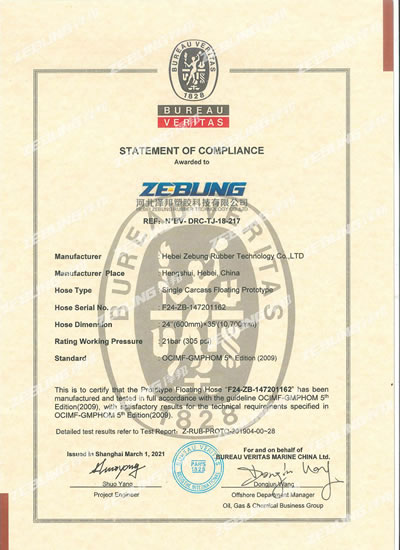

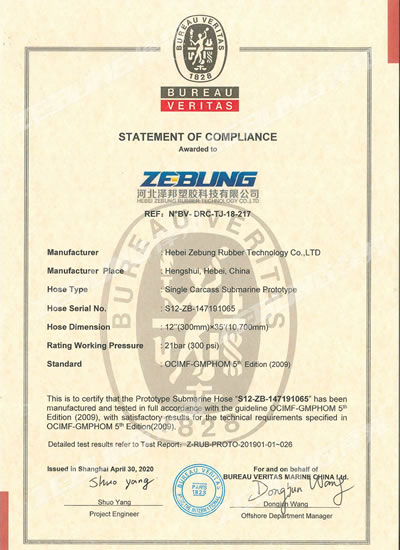

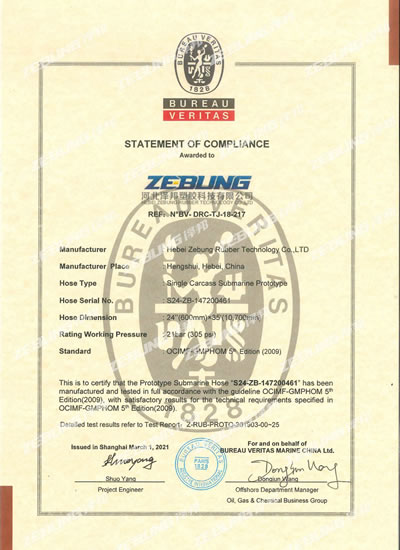

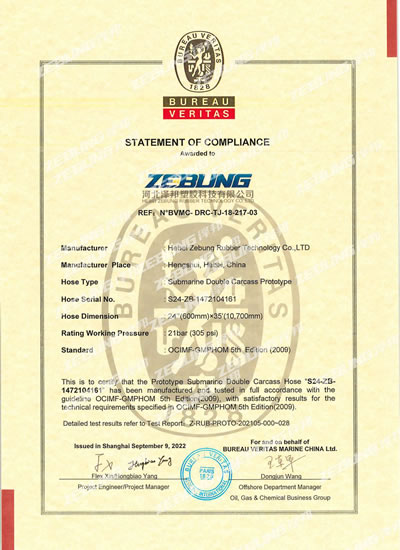

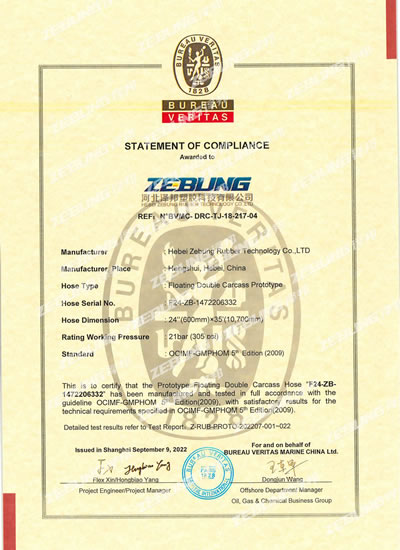

Certificates

-

BV Test Report (Single Carcass Floating Prototype-DN300mm)

BV Test Report (Single Carcass Floating Prototype-DN300mm) -

BV Test Report (Single Carcass Floating Prototype-DN600mm)

BV Test Report (Single Carcass Floating Prototype-DN600mm) -

BV Test Report (Single Carcass Submarine Prototype-DN300mm)

BV Test Report (Single Carcass Submarine Prototype-DN300mm) -

BV Test Report (Single Carcass Submarine Prototype-DN600mm)

BV Test Report (Single Carcass Submarine Prototype-DN600mm) -

BV Test Report (Submarine Double Carcass Prototype-DN600mm)

BV Test Report (Submarine Double Carcass Prototype-DN600mm) -

BV Test Report (Floating Double Carcass Prototype-DN600mm)

BV Test Report (Floating Double Carcass Prototype-DN600mm)