- Home

- Products

- Marine Hose

- Submarine Hose

- One End Reinforced Submarine Hose with Collars

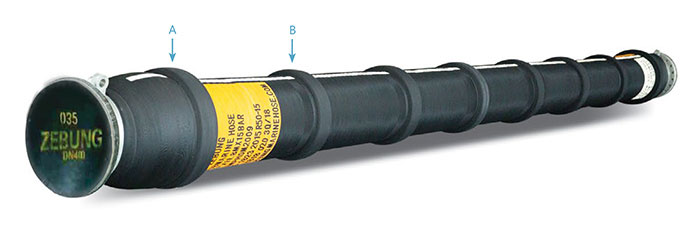

One End Reinforced Submarine Hose with Collars

With nearly two decade experience in marine hoses, Zebung is able to design and manufacture the best fitted submarine hoses after taking into consideration many factors such as water depth, tide, buoy excursions and wave patterns. Single carcass hose and double carcass hose with specified specifications can be made.

In order to guarantee high quality, the lining of the submarine hose is manufactured using textile reinforced bonded elastomers. This one end reinforced subsea hose is used for connecting with single point mooring (SPM) system and subsea manifolds, which is suitable for continuous fluid transporting at 21 m/s flow rate.

Standards

Our submarine hoses are designed and manufactured in accordance with OCIMF standard, and are certified by ISO 9000:2001 quality management system.

Technical Parameters

(Following data set under rated working pressure of 15, 19 or 21 bar)

| Inner Diameter mm |

Weight in Air Empty kg |

Outside Diameter mm |

Min. Bending Radius m |

|||

| 9.1m | 10.7m | 12.2m | A | B | ||

| 150(6") | 382/144 | 419/161 | 456/178 | 368 | 254 | 0.6(2.0') |

| 200(8") | 485/218 | 541/243 | 596/268 | 471 | 311 | 0.8(2.8') |

| 250(10") | 575/286 | 756/315 | 837/344 | 471 | 368 | 1.0(3.3') |

| 300(12") | 893/327 | 1003/372 | 1013/417 | 581 | 471 | 1.2(4.0') |

| 400(16") | 1808/659 | 2028/726 | 2248/793 | 697 | 581 | 1.6(5.3') |

| 500(20") | 2412/928 | 2694/1019 | 2976/1110 | 799 | 697 | 2.0(6.6') |

| 600(24") | 3369/1367 | 3775/1572 | 4181/1659 | 946 | 799 | 2.4(8.0') |

Note: Specifications can be made upon request.

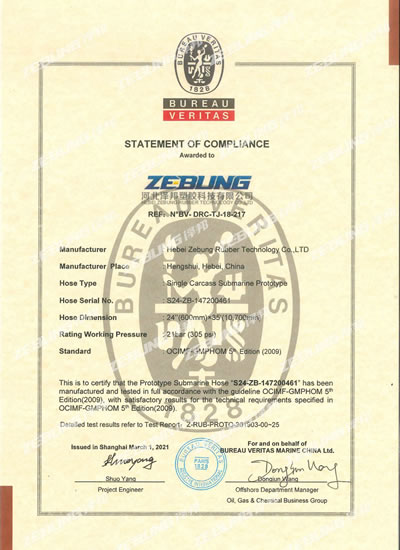

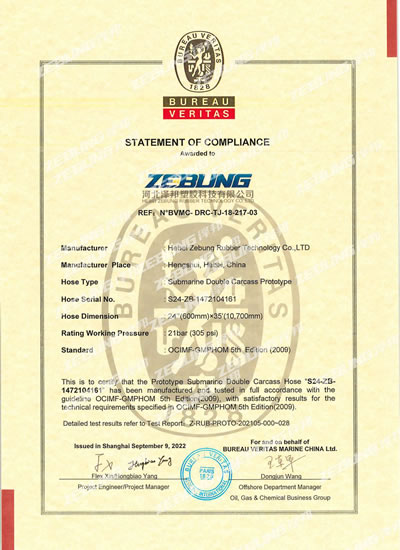

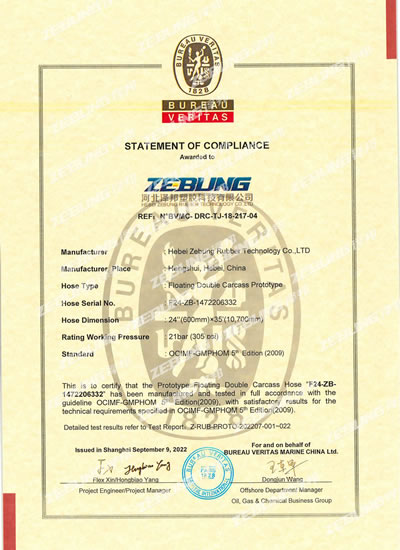

Certificates

-

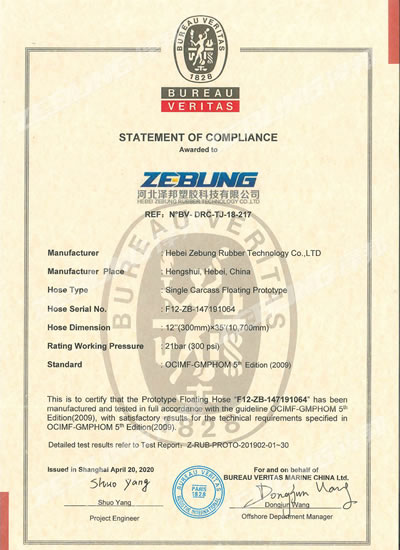

BV Test Report (Single Carcass Floating Prototype-DN300mm)

BV Test Report (Single Carcass Floating Prototype-DN300mm) -

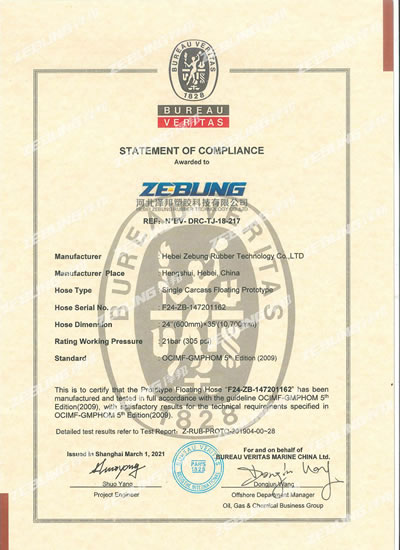

BV Test Report (Single Carcass Floating Prototype-DN600mm)

BV Test Report (Single Carcass Floating Prototype-DN600mm) -

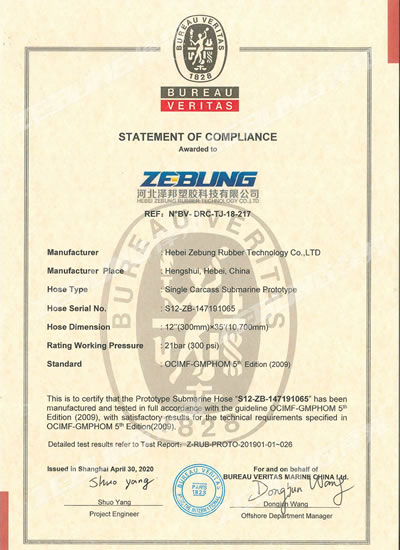

BV Test Report (Single Carcass Submarine Prototype-DN300mm)

BV Test Report (Single Carcass Submarine Prototype-DN300mm) -

BV Test Report (Single Carcass Submarine Prototype-DN600mm)

BV Test Report (Single Carcass Submarine Prototype-DN600mm) -

BV Test Report (Submarine Double Carcass Prototype-DN600mm)

BV Test Report (Submarine Double Carcass Prototype-DN600mm) -

BV Test Report (Floating Double Carcass Prototype-DN600mm)

BV Test Report (Floating Double Carcass Prototype-DN600mm)