Dredge Hose

-

A single foam floating layer prevents water absorption. The hose emergence above the water is not less than 20% of the total volume.

Custom flanges available.

-

Our discharge dredge hose is used for port and dock discharging of seawater, silt, sand and other dredging materials. The discharge hose features excellent stiffness and resistance to external physical damage.

-

Suction dredge hoses are designed for silt conveyance dredging operations. The smooth interior of the hoses help prevent clogs and avoids damage from the abrasive materials passing through.

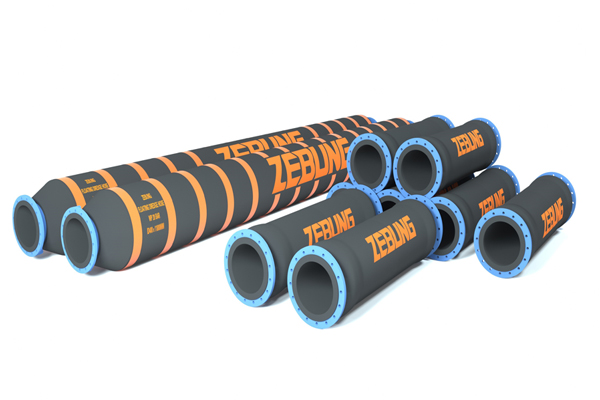

Our dredge hose line includes floating dredge hoses, discharge dredge hoses, suction hoses and armored hoses.

1. Hoses can be supplied in bore diameters from150 mm(6") up to900mm(36"), or larger upon request

2. Available in lengths up to11.8 m

3. Suitable for working pressures up to 30 bar

4. Available in either floating or submarine designs

5. Complementary sleeve designs suitable for suction or discharge service

6. Manufactured in accordance with ISO 9001:2000 quality standards (latest edition)

Structure

Lining

The synthetic rubber used for the lining of the hoses achieves maximum adhesion that is resistant to corrosion and damage during use.

Reinforcement

Multiple layers of high tensile strength reinforcement materials help prevent fatigue and physical damage, while maintaining flexibility. Fully embedded steel wire coils are incorporated prevent kinking and crushing.

Cover

The outer cover of the rubber hose is resistant to abrasion and wear caused by sea water and oil exposure. It features a bright orange spiral stripe coated in tough bright orange polyurethane.

Advantages

The dredge hose features light weight, high strength and flexibility. It is abrasion resistant, corrosion resistant, ultraviolet resistant and anti-aging. This marine hose can be connected directly through the flange. The transmission efficiency is higher than that of the steel tube by 20%-30% because of its friction coefficient. It can be used for a long term installation in water or on land.

Applications

The dredge hose is used for the engineering of waterway clean-ups, dredging, pumping sand, land reclamation, port expansion, and other mud or mortar conveying operations.