We specialize in producing a wide range of fluid conduit products to cater to various industries' needs. Our offerings include marine oil hoses, chemical hoses, food-grade hoses, air and water hoses, with diameters ranging from 6mm to 1150mm. Additionally, we provide suction and discharge oil hoses, dock oil hoses, sandblast hoses, and cement hoses. To further enhance our capabilities, we've recently installed a new production line dedicated to manufacturing large-diameter 50-meter dock oil hoses. This expansion underscores our commitment to meeting our customers' diverse requirements. Furthermore, we've invested in state-of-the-art VP fully automatic industrial fluid hose production lines imported from Italy. With over 120 sets of production equipment and 14 modern production lines, we ensure consistent quality and efficiency to meet our clients' demands.

Our raw material control is carefully overseen by our Chief Materials Engineer at Zebung, who brings over 30 years of expertise in the rubber industry. Supporting this, our research and development team consists of graduates from chemical engineering and materials science disciplines. We take pride in our self-sufficiency, independently researching and producing the rubber used in our hoses, ensuring adherence to rigorous testing standards, including compliance with the GMPHOM 2009 guidelines. Furthermore, our hoses are crafted from carefully selected natural rubber imported from Thailand and nitrile butadiene rubber (NBR) sourced from South Korea, chosen for their exceptional heat resistance.

-

Rubber Mixing Workshop

Our rubber mixing facility blends rubber compounds with precision, ensuring quality and consistency. With an annual capacity of 5000 tons, we employ advanced equipment for batching, mixing, and cutting, guaranteeing excellence in our rubber materials.

-

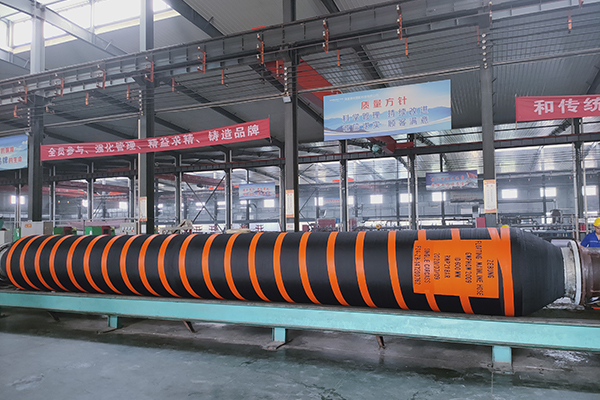

Hose Manufacturing Workshop

At our hose manufacturing hub, we excel in producing hoses to meet diverse needs. With capacities of 5 million standard meters for industrial hoses and 500 units for marine oil hoses annually, we utilize cutting-edge equipment for shaping and cutting, delivering exceptional quality and reliability.

Our company conducts thorough inspections of rubber hoses to uphold quality standards. This includes verifying the size, quantity, and ensuring the accuracy of the mark contents , ensuring that they align with the product specifications. Furthermore, we meticulously measure both the inner and outer diameters of rubber water hoses to detect any significant deviations, thereby ensuring precise dimensions and reliable performance. Additionally, our dedication to quality is evident in our investment of 20% of annual profits towards research and development, driving innovation and excellence in our product range

Zebung thoroughly inspects every stage of the manufacturing process, from raw rubber materials to rubber sheets, and then to the final products. Our overarching aim involves using advanced machinery to meticulously measure and monitor product quality, ensuring adherence to strict standards throughout production and beyond.

-

One End Reinforced Half Floating Hose

One end reinforced half floating hose is used for connecting with the single point mooring buoy system or CALM (catenary anchor leg mooring) buoy system to transport crude oil and petroleum fluids between FPSO and tanker. -

Mainline Submarine Hose without Collars

Designed without float collars, the submarine hose is suitable for use in connecting with subsea manifolds, and main submarine pipelines fitted in the hose strings on the single buoy mooring system. -

Dock Oil Hose / STS Hose

The dock hose is a multi-purpose hose product specially designed for suction and discharge applications. This suction and discharge hose is suitable for connecting with tankers, barges, storage tanks, etc. to transfer petroleum product.